I

have a Delta Fox F46-717

lathe with a 750W motor (1HP)

with

a

variable belt and pulley speed transmission

10 speeds 500 - 2000 rpm

and swivelling head

for large pieces.

with a Vicmac 100 chuck

The

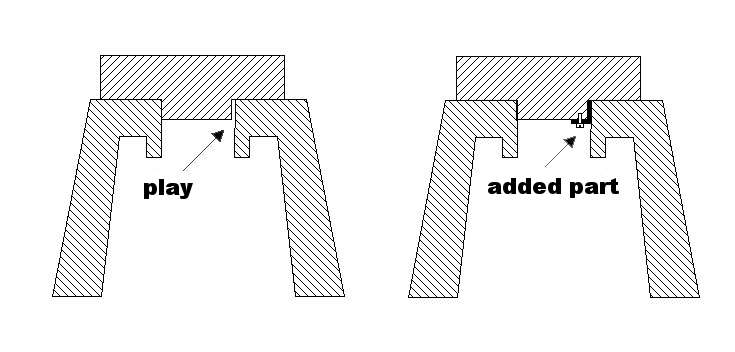

main problem of this lathe is the lack of precision in the alignment of

the

headstock and the tailstock and the locking mechanism of the head which

has an

annoying tendency to loosen because of vibrations, otherwise it is a

good lathe

to begin woodturning.